Erika Niino-Esser

thyssenkrupp Uhde

At the beginning of 2018, I started working as a development engineer for water electrolysis at thyssenkrupp nucera. At that time my vision was very clear: I wanted to contribute to a climate-friendly world by mastering the technology for green hydrogen production through utilization of renewable energies and help improve it. But did I have any idea of the importance this technology would have just a few years later? Certainly not.

Three years later I relocated to the United Arab Emirates, knowing that the Middle East is especially suitable for green hydrogen production. One has to see and experience the Middle East with your own eyes to realize the enormous potential of the region compared to the rest of the world. Oman in particular offers abundant renewable energy in both solar and wind power. Picturing a GW-scale green hydrogen project being realized in a few years increases my motivation and purpose significantly.

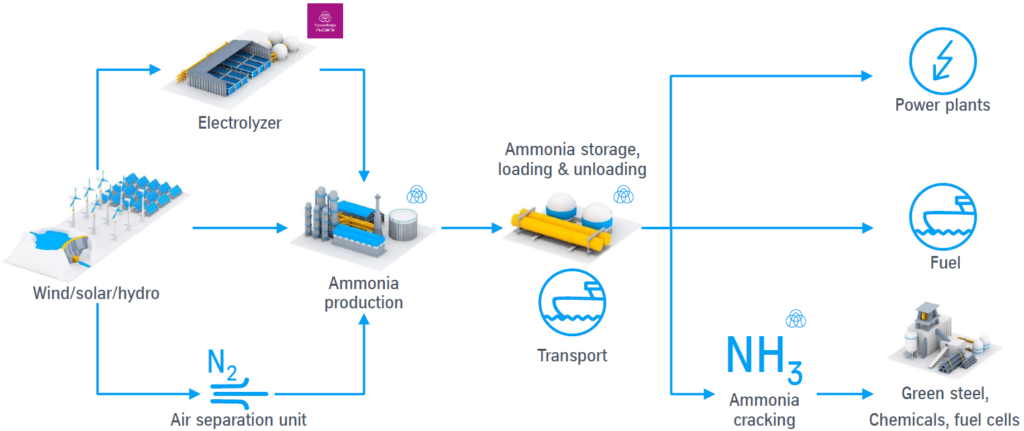

At the same time, I also believe that green hydrogen production alone will not be enough to reach the climate goals on time. A subsequent green ammonia production to establish a reliable hydrogen carrier will also be of immense importance. I hope to cause no misunderstanding: I am convinced that all kinds of hydrogen carriers are essential for exporting the “new oil” from the Middle East to off-takers in Europe or Asia. Several studies have been published by renowned organizations, in which pros and cons of different hydrogen carriers have been thoroughly analyzed already. In this brief article, I would like to take the opportunity to shed some light on the aspects of using ammonia as an energy carrier.

Ammonia is not only an intermediate product for fertilizer production but serves as a promising energy and hydrogen carrier when it comes to global trading. To highlight the facts here, around 180 million metric tons of ammonia are produced across the world, out of which 20 million metric tons are traded, annually. Of course, a substance like ammonia is never meant for end consumers and will only see professional use. But did you know that ammonia transportation is state of the art, and existing infrastructure can be utilized for distribution? The numbers are astonishing: an incredible number of 120 ports are already able to handle ammonia and up to 170 ships are suitable for carrying this base chemical. More importantly, 40 ships already conduct ammonia shipment all the time. You can see: Global standards, measures and procedures for safe storage and handling are already established worldwide.

Clean ammonia especially makes sense if the end-users are interested in ammonia as a base chemical or other direct uses. The majority of ammonia, namely 80 % is utilized for fertilizer production, hence implicitly, food production. The remaining 20 % are needed for other purposes, such as refrigerants, pharmaceuticals, or chemical products. Now, new applications for ammonia are becoming more and more attractive.

In gas turbines, clean ammonia can be used for co-firing to reduce emissions in electricity generation. And turbines for 100% ammonia are being developed, effectively enabling zero emission energy generation as water and nitrogen are the only emissions in this process. The same is true for using ammonia to power transport ships, which is gaining more and more interest from shipping companies. So, ammonia all by itself is incredibly versatile, and while direct use is the most cost-effective solution, it is also possible to reconvert ammonia into hydrogen and nitrogen. The process is called ammonia cracking and represents a reverse reaction of ammonia production. Colleagues at thyssenkrupp Uhde are currently working on this technology, and I am very excited about the development of this future-oriented technology.

As thyssenkrupp, we used to be technology providers for the chemical industry. Our new strength is to connect chemistry and energy, so we can meet our decarbonization targets and achieve net-zero as soon as possible. Thank you, Green Hydrogen Summit Oman for creating an open space to exchange about the vision for a sustainable hydrogen economy!

Clean ammonia especially makes sense if the end-users are interested in ammonia as a base chemical or other direct uses. The majority of ammonia, namely 80 % is utilized for fertilizer production, hence implicitly, food production. The remaining 20 % are needed for other purposes, such as refrigerants, pharmaceuticals, or chemical products. Now, new applications for ammonia are becoming more and more attractive.

In gas turbines, clean ammonia can be used for co-firing to reduce emissions in electricity generation. And turbines for 100% ammonia are being developed, effectively enabling zero emission energy generation as water and nitrogen are the only emissions in this process. The same is true for using ammonia to power transport ships, which is gaining more and more interest from shipping companies. So, ammonia all by itself is incredibly versatile, and while direct use is the most cost-effective solution, it is also possible to reconvert ammonia into hydrogen and nitrogen. The process is called ammonia cracking and represents a reverse reaction of ammonia production. Colleagues at thyssenkrupp Uhde are currently working on this technology, and I am very excited about the development of this future-oriented technology.

As thyssenkrupp, we used to be technology providers for the chemical industry. Our new strength is to connect chemistry and energy, so we can meet our decarbonization targets and achieve net-zero as soon as possible. Thank you, Green Hydrogen Summit Oman for creating an open space to exchange about the vision for a sustainable hydrogen economy!